电芯化成分容方案

是恒翼能针对电池电芯生产线提供的整体规划服务, 从扫码装盘到分档配对,依据电池生产工艺做最适当的系统性规划, 包含仪器设备构建、物流规划、生产管理系统等, 提供多样客制功能,量身打造高效益产线。 同时我司基于业内客户特点,结合自身丰富行业经验致力于帮助客户提升生产效率, 降低生产成本,并实现生产制造的数字化、柔性化甚至智能化, 从而提出锂电池模组及PACK自动生产线整体解决方案, 包括机器人自动分选、配组、焊接、装配、测试、包装等整套生产流程, 适用于圆柱电池、方形电池、软包电池。此外针对锂电池的安全, 国际和国内多项功能和性能标准要求 容量、能量、功率、效率、标准循环寿命、工况循环寿命、荷电保持、容量恢复、倍率性能、高低温性能等提供测试方案和产品。.jpg) Formation and capacity-grading plan of Prismatic cell

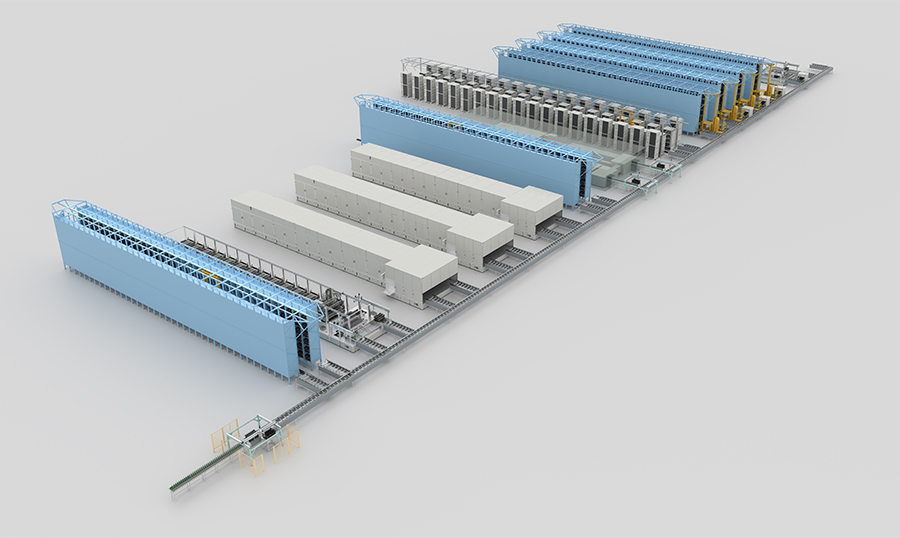

Formation and capacity-grading plan of Prismatic cell

The overall solution of battery formation and capacity grading is a planning service provided by HYNN for the battery cell production line. From code scanning, loading onto tray and hierarchy pairing, we make the most appropriate systematic planning based on battery production process, including the equipment construction, logistics planning, production management systems and so on. We provide a variety of customized functions and offer tailored high-yield production lines.

Formation and capacity-grading plan of Pouch cell

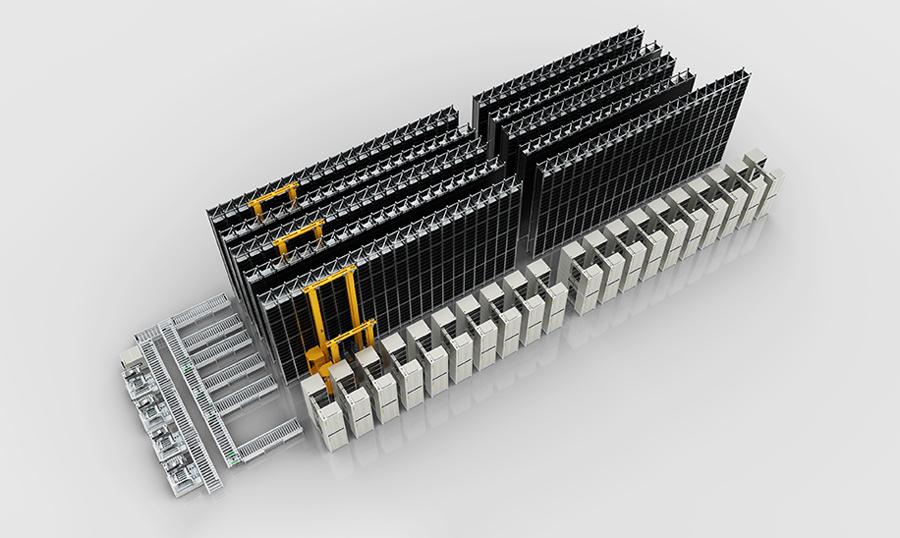

Formation and capacity-grading plan of Pouch cell

The overall solution of battery formation and capacity grading is a planning service provided by HYNN for the battery cell production line. From code scanning, loading onto tray and hierarchy pairing, we make the most appropriate systematic planning based on battery production process, including the equipment construction, logistics planning, production management systems and so on. We provide a variety of customized functions and offer tailored high-yield production lines.

Formation and capacity-grading plan of Cylindrical cell

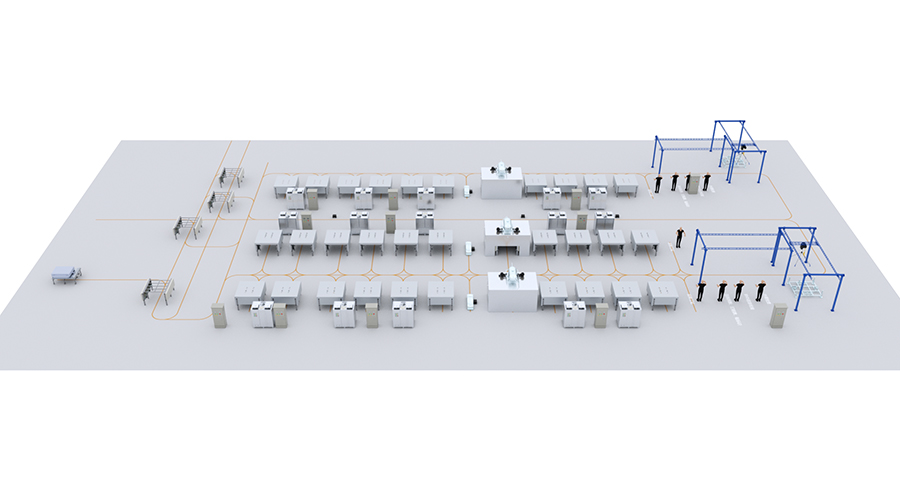

Formation and capacity-grading plan of Cylindrical cell

The overall solution of battery formation and capacity grading is a planning service provided by HYNN for the battery cell production line. From code scanning, loading onto tray and hierarchy pairing, we make the most appropriate systematic planning based on battery production process, including the equipment construction, logistics planning, production management systems and so on. We provide a variety of customized functions and offer tailored high-yield production lines.

Module and PACK automatic production line

Module and PACK automatic production line

In recent years, with the rapid development of new energy industry, the new energy automobile and power battery industry is upgrading constantly, and battery plants have more and more requirements for automation and compatibility. Our company is committed to helping customers to improve production efficiency, lower production costs and achieve digitization, flexibility and even intelligentization for production and manufacture; and proposing overall solution of lithium battery module and PACK line, including the complete production process of automatic sorting by robot, matching, screwing, welding, assembly, testing and packaging. We are also committed to customizing automated solution for customers, which applies in cylindrical battery, square-shell battery and soft packing battery.

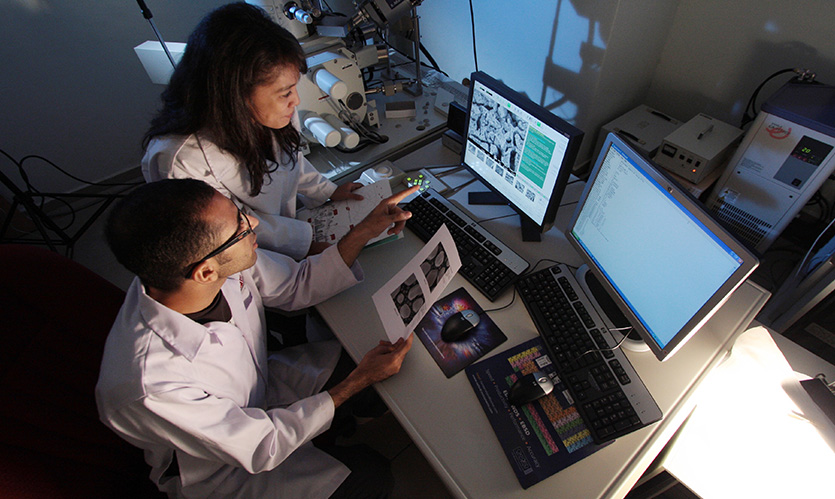

Lab application scheme

Lab application scheme

For the safety of lithium batteries, we provide testing solutions and products for battery capacity, energy, power, efficiency, standard life cycle, operation life cycle, charging retention, capacity recovery, rate performance, high and normal temperature performance, and etc.

Other

Other

The overall solution of battery formation and capacity grading is a planning service provided by HYNN for the battery cell production line. From code scanning, loading onto tray and hierarchy pairing, we make the most appropriate systematic planning based on battery production process, including the equipment construction, logistics planning, production management systems and so on. We provide a variety of customized functions and offer tailored high-yield production lines.

并以专业的设计、快速交付的能力与优质服务,逐渐在业界树立起重品质、守信誉、优服务的品牌形象。